ReverseEngineering.com® Launches 2026 Autodesk Fusion Add-In for Portable CMMs, Closed-Loop Shop Floor Measurement

Best for: Comprehensive point cloud to solids, complex parametric geometries, and scan-to-drawing for manufacturing in real time

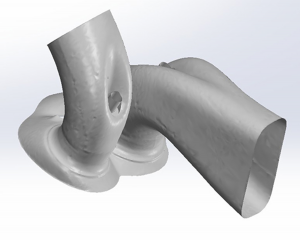

When reverse engineering an exhaust port, we need 300 splines at 0.05" offsets—ReverseEngineering.com lets us scan, model, validate, and generate drawings all in one seamless Fusion workflow.”

LA JOLLA, CA, UNITED STATES, October 28, 2025 /EINPresswire.com/ -- ReverseEngineering.com® Launches 2026 Autodesk Fusion Add-In for Portable CMMs, Enabling Real-Time Closed-Loop Shop Floor Measurement— Braxton Carter application engineer at ReverseEngineering.com

Best for: Comprehensive point cloud to solids, complex parametric geometries, and scan-to-drawing for manufacturing in real time

ReverseEngineering.com®, a registered trademark and DBA of HighRES, Inc., today announced its 2026 Autodesk Fusion Add-In for Portable CMMs—a fully digital, closed-loop measurement solution that redefines reverse engineering workflows and boosts shop floor efficiency.

The add-in integrates natively with FARO Probe Manager, Hexagon RDS, and leading PCMM hardware—including FARO Quantum X, Hexagon Absolute Arm, ROMER Arms, and compatible laser scanners. It delivers seamless probe calibration, real-time data capture, and parametric CAD modeling—all within a single Autodesk Fusion environment.

Powered by proprietary ScanToCAD Push Technology™, the platform extracts feature-based geometry from dense point clouds and instantly converts it into editable CAD features. Engineers can generate solids, parametric surfaces, and production-ready drawings directly from scan data—eliminating manual modeling and enabling real-time scan-to-drawing workflows.

“When reverse engineering an engine exhaust port, designers need precision splines at precision offsets with full node-to-node continuity,” said Braxton Carter application engineer at ReverseEngineering.com . “The 2026 add-in delivers this natively in Fusion—allowing us to scan, model, validate, and generate production-ready drawings in one seamless, real-time workflow.”

Unlike static STL meshes, the solution generates fully editable CAD models with live deviation analysis—supporting true closed-loop Design-to-Manufacturing (D2M) cycles for industries demanding speed, precision, and traceability.

________________________________________

Key Capabilities:

• Real-time probe and scanner data streaming into Autodesk Fusion

• Automated feature recognition and surface reconstruction

• Comprehensive point cloud to solids conversion

• Complex parametric geometry creation with full history tree control

• Scan-to-drawing for manufacturing (with GD&T, dimensions, and tolerance annotations)

• Closed-loop validation with on-arm re-measurement—no tool switching or file transfers

• Full compatibility with FARO®, Hexagon®, and third-party PCMMs

• ISO 10360-12 certified accuracy and NIST traceability

________________________________________

About ReverseEngineering.com®

ReverseEngineering.com®, a registered trademark and DBA of HighRES, Inc., is the global leader in CAD-native ScanToCAD and reverse engineering software. With over 5,000 installations worldwide, its add-ins enable real-time measurement, modeling, inspection, and manufacturing preparation inside Autodesk Fusion 360®, SOLIDWORKS®, Mastercam®, Autodesk Inventor®, Ansys Discovery®, Siemens NX®, and Solid Edge®.

ScanToCAD Push Technology™ instantly transfers 3D scan data into native CAD features—eliminating manual steps and enabling live validation, re-measurement, and design updates without leaving the CAD environment.

Trusted across aerospace, automotive, medical, and defense industries, ReverseEngineering.com® is an Autodesk Certified Partner and a SOLIDWORKS Certified Gold Partner.

Media Contact:

Amanda Blake

Media Relations

mediarelations@reverseengineering.com

+1-858-488-5231

Demo Video: https://reverseengineering.com/autodesk-fusion-360-2/

________________________________________

ReverseEngineering.com® is a registered trademark of HighRES, Inc. Autodesk®, Fusion 360®, and Inventor® are registered trademarks of Autodesk, Inc. SOLIDWORKS® is a registered trademark of Dassault Systèmes. All other trademarks are the property of their respective owners.

Amanda Blake

ReverseEngineering.com

+1 858-488-5231

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

3D Scan result of Engine port

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.